Steel fiber and synthetic fiber are two types of fibers that are commonly used in various applications. While they share some similarities, they also have some key differences. In this article, we will explore the differences between steel fiber and synthetic fiber, and discuss their unique properties and uses.

Steel Fiber:

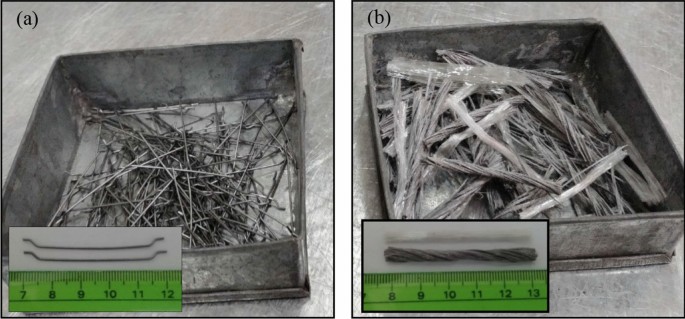

Steel fiber vs synthetic fiber: Steel fiber is a type of fiber made from steel, which is a combination of iron and carbon. It is produced by drawing steel wire through a series of dies to create a thin, flexible strand. Steel fiber has a high strength-to-weight ratio, making it ideal for applications where strength and durability are important.

Synthetic Fiber:

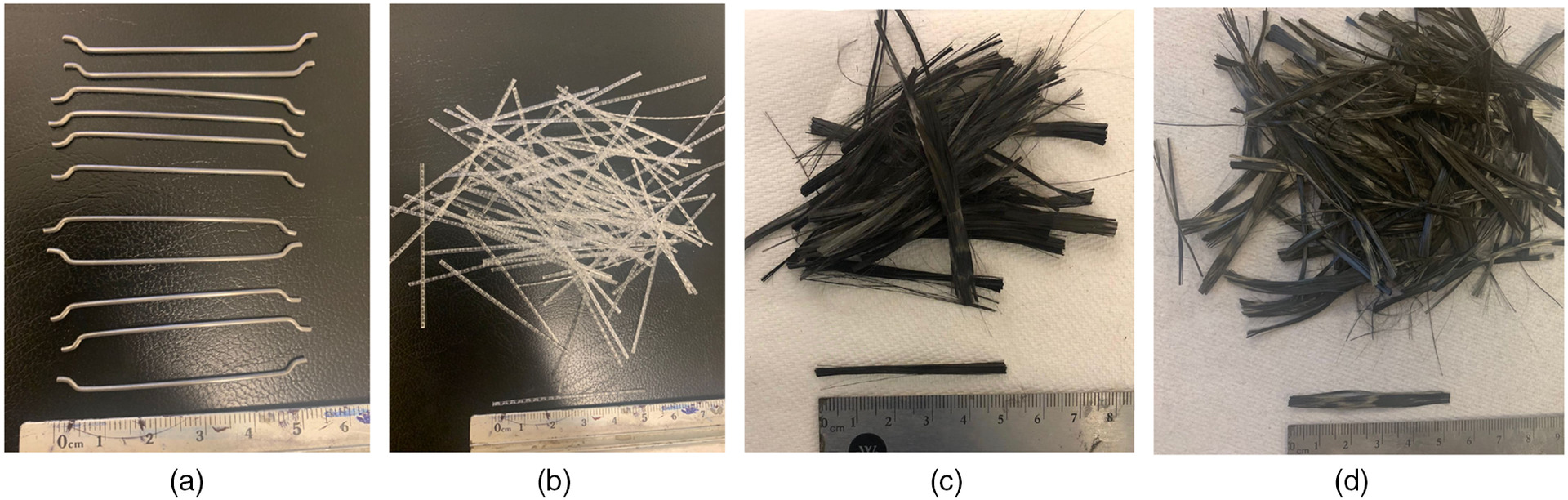

Synthetic fiber, on the other hand, is made from synthetic materials such as polyester, nylon, and rayon. It is produced through a process called extrusion, where the synthetic material is melted and formed into a strand. Synthetic fiber has a lower strength-to-weight ratio compared to steel fiber, but it is more flexible and has better resistance to heat and chemicals.

Differences between Steel Fiber and Synthetic Fiber:

Strength: Steel fiber has a higher strength-to-weight ratio compared to synthetic fiber. This means that it can withstand more stress and strain without breaking, making it ideal for applications where strength is critical.

Durability: Steel fiber is more durable than synthetic fiber, meaning it can withstand more wear and tear over time. This makes it a better choice for applications where the fiber will be subjected to harsh conditions.

Flexibility: Synthetic fiber is more flexible than steel fiber, making it easier to bend and shape. This makes it a better choice for applications where the fiber needs to be flexible, such as in clothing or upholstery.

Resistance to Heat and Chemicals: Synthetic fiber has better resistance to heat and chemicals compared to steel fiber. This makes it a better choice for applications where the fiber will be exposed to high temperatures or harsh chemicals.

Applications of Steel Fiber and Synthetic Fiber:

Steel fiber is commonly used in construction, automotive, and industrial applications where strength and durability are important. It is often used in reinforced concrete, where it helps to improve the strength and durability of the concrete. Steel fiber is also used in composite materials, where it provides additional strength and stiffness.

Synthetic fiber, on the other hand, is commonly used in clothing, upholstery, and carpeting. It is also used in industrial applications where the fiber needs to be flexible, such as in conveyor belts and machine components. Synthetic fiber is also used in medical applications, where its resistance to heat and chemicals makes it ideal for use in medical implants and devices.

Conclusion:

In conclusion, steel fiber and synthetic fiber are two types of fibers with different properties and uses. Steel fiber has a higher strength-to-weight ratio, making it ideal for applications where strength and durability are important.

Synthetic fiber, on the other hand, is more flexible and has better resistance to heat and chemicals, making it a better choice for applications where flexibility and resistance to harsh conditions are important. By understanding the differences between these two types of fibers, manufacturers can choose the right fiber for their specific application.