Steel fibers are an essential component in the production of reinforced concrete, used to enhance the durability and strength of the material. High tensile steel fibers are a specific type of steel fiber that offers superior performance and durability. In this article, we will explore the different types of steel fibers, with a focus on high tensile steel fibers.

Types of Steel Fibers

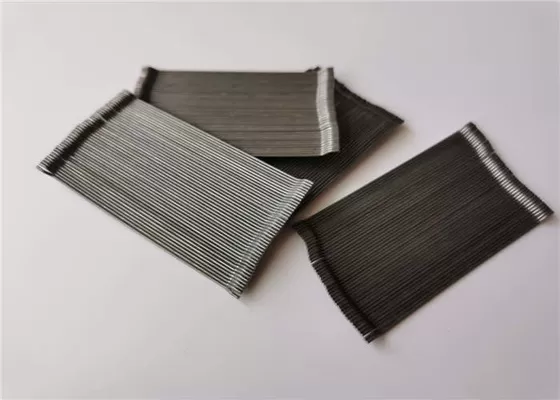

Steel fibers are categorized into three main types based on their shape:

- Straight fibers: These fibers are straight and have a circular cross-section. They are the most commonly used type of steel fiber and are often used in concrete structures such as bridges, high-rise buildings, and roads.

- Deformed fibers: These are straight but have a deformed or crushed cross-section. They provide a better grip between the concrete and the fiber, which enhances the bond between the two materials. Deformed fibers are commonly used in structures that require high durability and resistance to cracking, such as in marine environments.

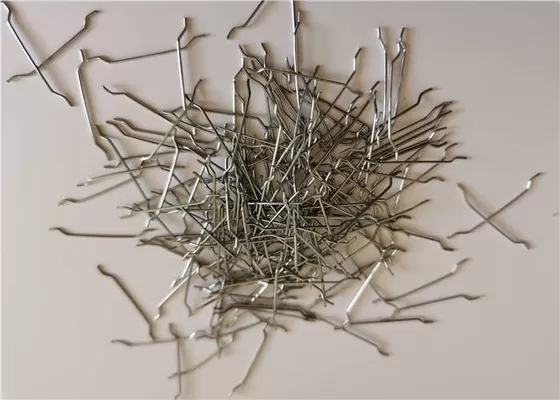

- Crimped fibers: These fibers are spiral-shaped and have a circular cross-section. They provide better flexibility and are often used in structures that require high tensile strength, such as in earthquake-resistant construction.

High Tensile Steel Fibers

High tensile steel fibers are a type of deformed fiber that offers superior performance and durability. They are made from a high-strength steel alloy that is resistant to corrosion and has a high tensile strength.

High tensile steel fibers are used in structures that require high durability and resistance to cracking, such as in marine environments, and in structures subjected to high loads and stresses, such as earthquake-resistant construction.

Advantages of High Tensile Steel Fibers

High tensile steel fibers offer several advantages over other types of steel fibers, including:

- Superior durability: High tensile steel fibers are corrosion-resistant and have a high tensile strength, making them ideal for use in harsh environments.

- Improved crack resistance: The deformed shape of high tensile steel fibers provides a better grip between the concrete and the fiber, which enhances the bond between the two materials and reduces the risk of cracking.

- Increased tensile strength: High tensile steel fibers have a higher tensile strength than other types of steel fibers, making them ideal for use in structures that require high tensile strength, such as in earthquake-resistant construction.

- Reduced shrinkage: High tensile steel fibers have a lower shrinkage rate than other types of steel fibers, which reduces the risk of shrinkage cracking in the concrete.

Conclusion

High tensile steel fibers are a superior type of steel fiber that offers many advantages over other types of steel fibers. They are ideal for use in structures that require high durability and resistance to cracking, such as in marine environments.

And in structures subjected to high loads and stresses, such as earthquake-resistant construction. By incorporating high tensile steel fibers into their designs, engineers, and architects can create structures that are stronger, more durable, and more resistant to cracking.