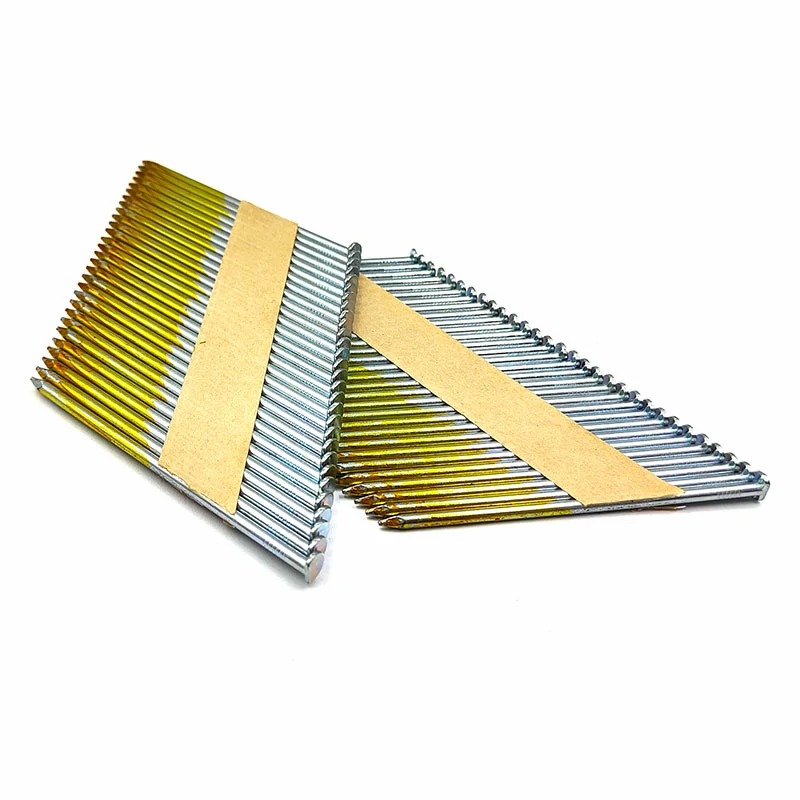

The galvanizing process primarily impacts the surface of nails, including 34-degree nails, by providing a protective coating that helps prevent corrosion. The process involves applying a layer of zinc to the nail’s surface through either hot-dip galvanizing or electro-galvanizing. It is important to note that the galvanizing process itself does not significantly affect the strength and hardness of the nails at their core.

Here’s how the galvanizing process works and its potential impact on the strength and hardness of 34-degree nails:

- Hot-Dip Galvanizing:

- In hot-dip galvanizing, the nails are immersed in a bath of molten zinc. The zinc bonds metallurgically with the steel, creating a zinc-iron alloy layer on the surface of the nail. This process adds a protective coating that helps prevent corrosion.

- Electro-Galvanizing:

- Electro-galvanizing involves passing an electric current through a zinc solution, depositing a layer of zinc onto the nail’s surface. This method also creates a zinc coating, providing corrosion resistance.

- Impact on Strength and Hardness:

- The galvanizing process itself does not significantly alter the strength or hardness of the steel used in 34-degree nails. 34 degree nails The core strength and hardness are primarily determined by the composition and heat treatment of the steel before galvanizing.

- Potential for Heat Treatment:

- In some cases, nails may undergo heat treatment before or after galvanizing to achieve specific mechanical properties. Heat treatment can influence the hardness and strength of the steel. However, this is a separate process from galvanization.

- Careful Handling During Galvanizing:

- Care must be taken during the galvanizing process to minimize any potential for mechanical damage to the nails. Proper handling ensures that the nails retain their original mechanical properties.

- Consideration for Coating Thickness:

- The thickness of the galvanized coating can vary based on the galvanizing method and specifications. While thicker coatings provide enhanced corrosion resistance, they may also slightly affect the dimensions of the nails. Manufacturers carefully control the coating thickness to meet standards and specifications.

In summary, the galvanizing process primarily contributes to corrosion resistance rather than directly impacting the strength and hardness of 34-degree nails. The mechanical properties of the nails, including strength and hardness, are determined by the quality of the steel used and any additional heat treatment processes. It’s important for manufacturers and users to follow industry standards and specifications to ensure the proper performance of galvanized nails in construction applications.