This article explores the technology, advantages, applications, and maintenance of hooked end steel fiber in concrete construction. Discover how this innovative reinforcement material improves the strength and durability of concrete structures. Learn about the factors to consider when incorporating hooked end steel fiber into concrete and best practices for maintenance.

Introduction:

Hooked end steel fiber is a game-changing reinforcement material that enhances the performance of concrete structures. In this article, we delve into the world of hooked end steel fiber and its remarkable benefits. We explore its technology, advantages, and applications, and provide essential maintenance tips.

Whether you’re involved in residential, commercial, or infrastructure construction, understanding the potential of hooked end steel fiber will empower you to create stronger and more durable concrete structures.

Understanding Hooked End Steel Fiber Technology:

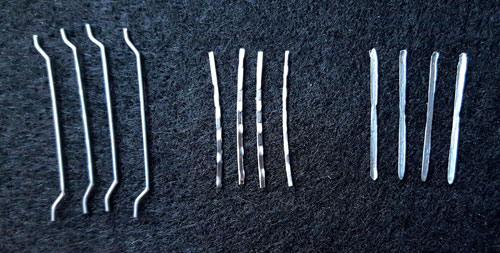

Hooked end steel fiber is a specially designed reinforcement material made from high-strength steel. Each fiber has a unique hooked end shape, which provides excellent bonding with the concrete matrix. This interlocking mechanism enhances the load-bearing capacity and crack resistance of the concrete, resulting in superior performance.

Advantages of Using Hooked End Steel Fiber in Concrete:

- Increased Strength: Hooked end steel fiber significantly enhances the tensile and flexural strength of concrete, making it more resistant to cracking and structural failure.

- Improved Durability: The addition of hooked end steel fiber improves the durability of concrete, making it more resistant to impact, abrasion, and fatigue.

- Enhanced Crack Control: The unique hooked end shape of the fibers helps to distribute stress within the concrete, reducing crack width and preventing crack propagation.

Applications of Hooked End Steel Fiber Reinforced Concrete:

- Industrial Flooring: Hooked end steel fiber is ideal for industrial flooring applications, providing exceptional load-bearing capacity and crack resistance.

- Shotcrete Applications: Incorporating hooked end steel fiber in shotcrete applications enhances the structural integrity and durability of sprayed concrete.

Factors to Consider When Incorporating Hooked End Steel Fiber into Concrete:

- Fiber Type and Dosage: Select the appropriate hooked end steel fiber type and dosage based on the specific performance requirements of your concrete mix.

- Mixing and Dispersion: Ensure proper mixing and dispersion of the fibers within the concrete to achieve uniform reinforcement distribution.

Maintenance and Best Practices for Hooked End Steel Fiber Reinforced Concrete:

- Regular Inspections: Perform routine inspections to identify any signs of fiber exposure, corrosion, or damage, and address them promptly.

- Proper Cleaning: Clean the reinforced concrete surfaces using suitable methods and avoid aggressive cleaning agents that may damage the fibers.

Conclusion:

Hooked end steel fiber is a revolutionary reinforcement material that elevates the performance of concrete structures. By understanding its technology, advantages, and applications, you can unlock the potential of this innovative material in your construction projects.

Consider the factors mentioned when incorporating hooked end steel fiber into your concrete mix and follow proper maintenance practices to ensure long-lasting performance. Maximize the strength, durability, and crack resistance of your concrete structures with the power of hooked end steel fiber.