This article provides an overview of the various uses and applications of 304 stainless steel angle iron, including its strengths, advantages, and common uses in different industries.

Introduction:

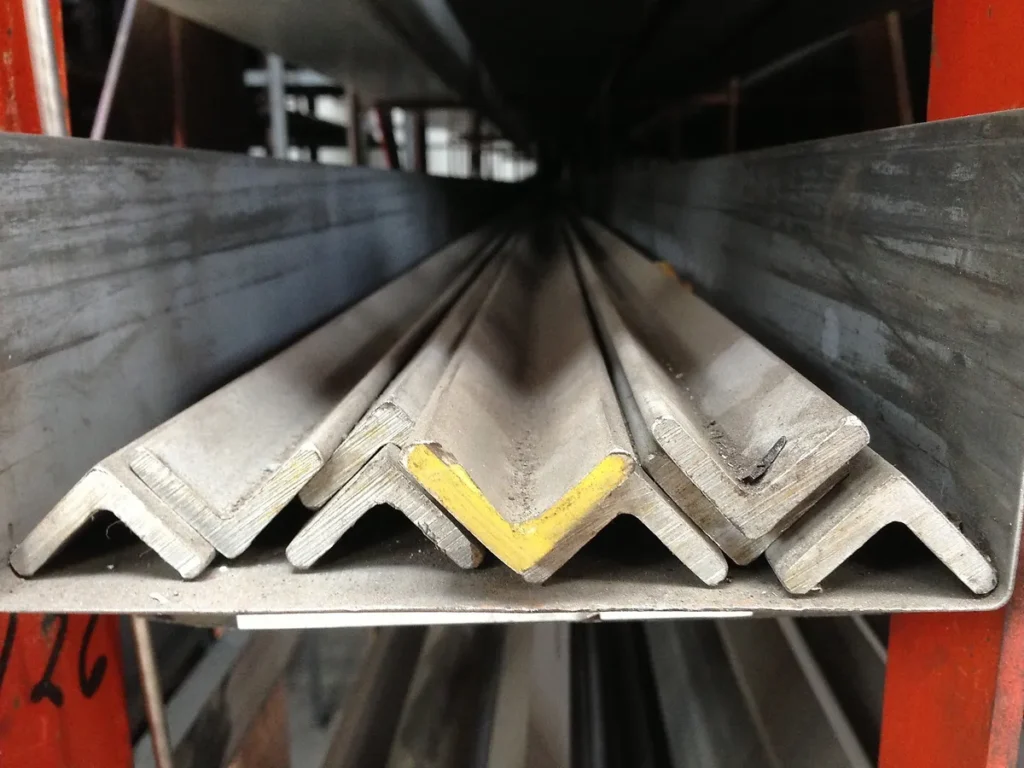

304 stainless steel angle iron is a versatile material that is widely used in various industries due to its strength, durability, and resistance to corrosion. It is a type of steel that is made by heating and rolling a sheet of metal into a desired shape.

Resulting in a strong and rigid structure with a smooth surface. In this article, we will explore the different uses and applications of 304 stainless steel angle iron, as well as its benefits and drawbacks.

Uses and Applications:

- Construction Industry: 304 stainless steel angle iron is commonly used in the construction industry for building structures such as bridges, buildings, and other infrastructure projects. Its high strength and durability make it an ideal choice for these applications.

- Automotive Industry: The automotive industry uses 304 stainless steel angle iron for various components such as engine mounts, suspension components, and exhaust systems. Its high strength and resistance to corrosion make it an ideal choice for these applications.

- Food Industry: The food industry uses 304 stainless steel angle iron for various equipment such as mixers, blenders, and cooking utensils. Its high strength and resistance to corrosion make it an ideal choice for these applications.

- Medical Industry: The medical industry uses 304 stainless steel angle iron for various medical equipment such as surgical instruments, hospital beds, and medical implants. Its high strength and resistance to corrosion make it an ideal choice for these applications.

Benefits:

- High Strength: 304 stainless steel angle iron has a high strength-to-weight ratio, making it an ideal choice for applications where weight is a concern.

- Durability: 304 stainless steel angle iron is highly resistant to corrosion and wear and tear, making it an ideal choice for applications where longevity is important.

- Resistance to Corrosion: 304 stainless steel angle iron is resistant to corrosion, making it an ideal choice for applications where exposure to chemicals or moisture is present.

- Versatility: 304 stainless steel angle iron can be easily cut, shaped, and formed to meet specific application requirements.

Drawbacks:

- High Cost: 304 stainless steel angle iron is more expensive than other types of steel, making it less accessible to some consumers.

- Limited Flexibility: While 304 stainless steel angle iron can be easily cut and shaped, it may not be as flexible as other materials in certain applications.

Conclusion:

In conclusion, 304 stainless steel angle iron is a versatile and durable material that is widely used in various industries due to its strength, durability, and resistance to corrosion. Its high strength-to-weight ratio makes it an ideal choice for applications where weight is a concern.

Its resistance to corrosion and wear and tear makes it an ideal choice for applications where longevity is important. While it may have a higher cost and limited flexibility compared to other materials, its benefits make it a popular choice for many industries.